Aluminum is used more and more in the shipbuilding industry, small from rafts, motorboats, large to 10,000 tons of wheels, from civilian to military, from high-speed hovercraft to deep-water submarines, from fishing boats to marine mining vessels, marine aluminium alloy plate materials are used as ship shells, superstructures, various facilities, piping, and appliances. The use of aluminum plate in shipbuilding not only saves resources and energy, protects the environment, and obtains huge social benefits, but also brings considerable economic benefits.

The ship’s construction and industrial environment require that the material should have good corrosion resistance, weldability, plasticity and certain resistance strength, yield strength, elongation, impact resistance and other properties. In order to meet these properties, the most suitable marine grade aluminum alloys for use on ships are industrial 5000 series and 6000 series alloys.

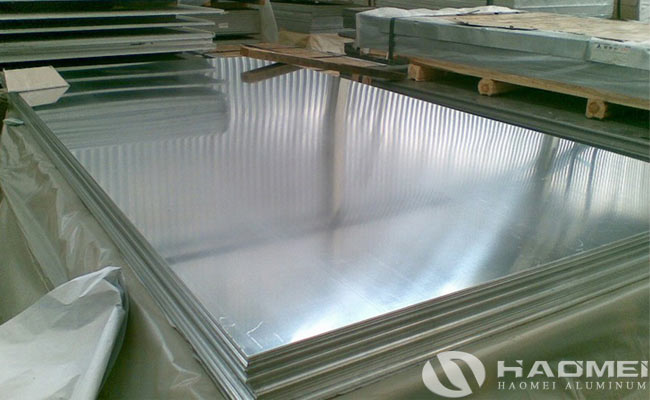

First, the 5083 5086 aluminum plate is a typical marine grade aluminum alloy, it has good weldability, corrosion resistance and low temperature performance, and is used to construct the main structure of the ship body.

Second, the 5052 aluminum plate has medium strength, good corrosion resistance and formability, and high fatigue resistance. Mainly used for ship superstructure, auxiliary components, small boat hull.

Third, the 6061 aluminum alloy is a heat-treated reinforced aluminum alloy with high strength and low single-welding strength, and is mainly used for a screw joint structure and a riveted structure which are not in contact with seawater.

The 5083 aluminum plate, 5086 marine aluminium alloy plate, 5052 aluminum plate and 6061 aluminum rod have been widely used in the field of ship parts processing.

Contact Us

- 1103, No.14 Waihuan Road, CBD,Zhengzhou, China

- +86-0371-65621391

- nydia@aluminumhm.com

- Contact Form